Product Center

About Us

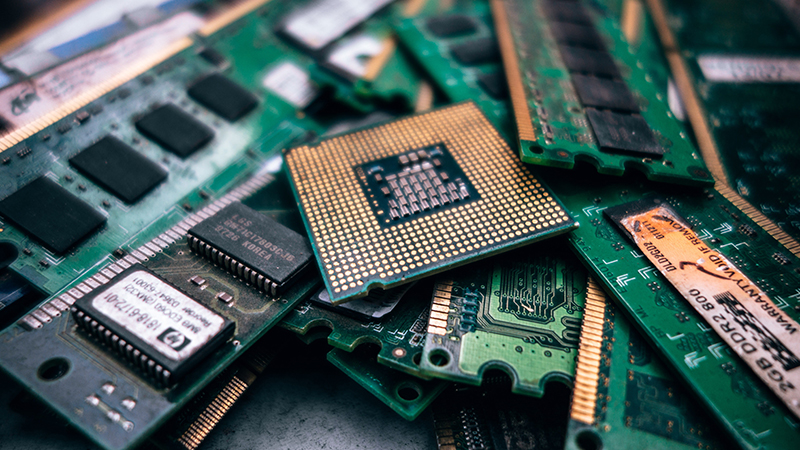

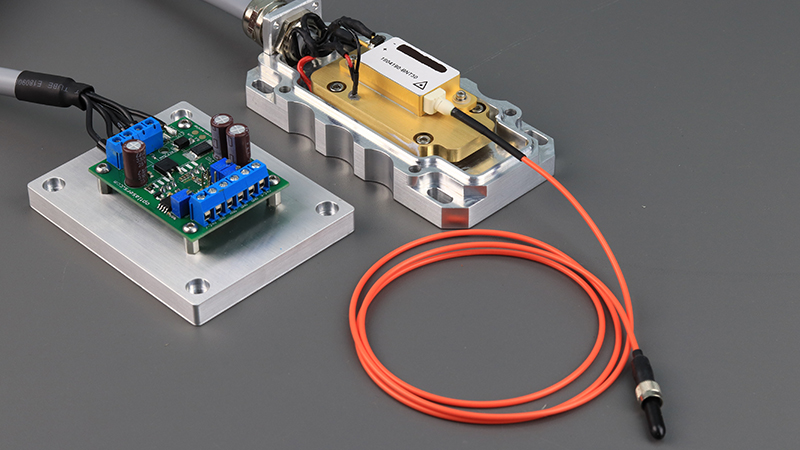

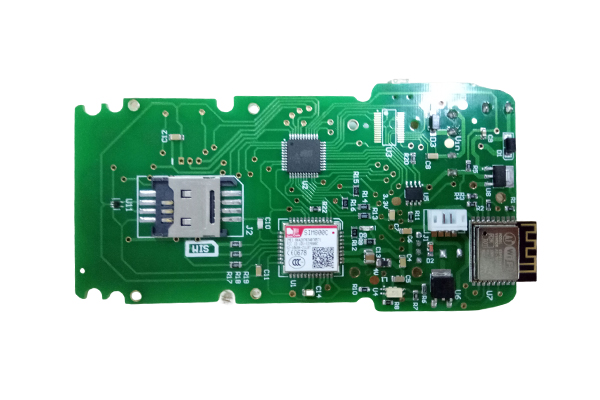

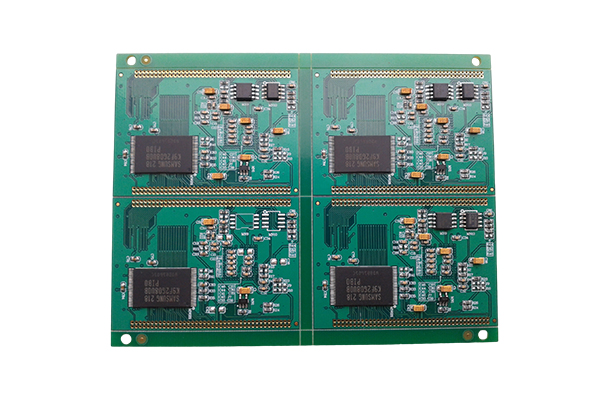

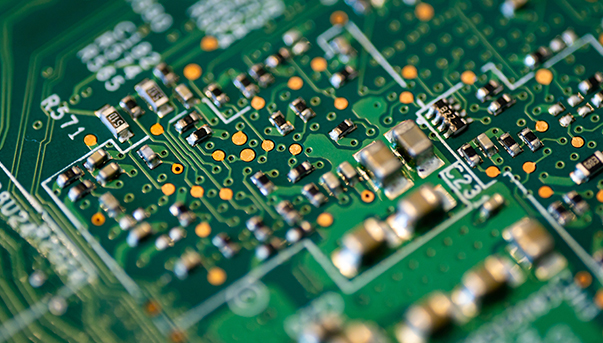

JF Technology Limited was founded in year of 2017, our aim is to support engineers to produce and verify their PCB designs. Our PCB and PCBA service is one-stop and customized. We own automatic SMT production lines and rich experiences in PCB and PCBA, our products have been widely used in communications, medical devices, industrial machines, automotive as well as instrument and other fields. Our team has been always adhering to our enterprise spirits of “quality first, service-oriented“ to make products and serve clients, Just like when our company begins. We believe our great craftsmanship would win more clients and more market recognition.

Manufacturing capability

For products quality, PCB reliability is the most essential part, as whole production processes go through a lot of procedures which requires highly cooperation between production staffs and machines. What’s more, Our quality management team are professional and experienced. All PCB will be checked by AOI machines and electrical test machines to ensure pass rate up to 100%.

With high speed development of semiconductor circuits and EDA designers pay more attention to quality level of PCB production, PCB manufacturing capabilities become more and more important. Continuous investment on new machines and upgrade production system could keep our PCB manufacturing capabilities ahead of other manufacturers.

Share Ideas and News With You